10 ton Jib Crane vs. 10 ton Bridge Crane vs. 10 ton Gantry Crane

Compare 10 ton jib crane, 10 ton bridge crane & 10 tongantry cranes for mobility, cost, space & ideal usage in material handling applications. Check now.

Category: 10 Ton Overhead Crane

Your Trusted 10 Ton Overhead Crane Manufacturer & Supplier

10 ton Material Handling: Jib Crane vs. Bridge Crane vs. Gantry Crane

Comparison: 10 ton Jib Crane vs. 10 ton Bridge Crane, vs, 10 Ton Gantry Crane

Compare 10 ton jib crane, 10 ton bridge crane & 10 tongantry cranes for mobility, cost, space & ideal usage in material handling applications. Learn more the features of the each type of 10 ton crane design to get the most suitable solution for your industrial applications.

Introduction:Overview of Material Handling Cranes

Selecting the right crane is crucial for efficient material handling. Cranes are used to lift, move, and position heavy loads in various environments, such as factories, warehouses, and construction sites. The right crane improves workflow, reduces downtime, and boosts safety.

There are different types of cranes designed for different purposes. Knowing which one fits your needs will help you make the best decision.

Importance of Selecting the Right Crane for Specific Needs

Each type of crane has unique features, and choosing the right one can make a significant difference in your operations. Selecting the wrong crane could lead to:

- Inefficiency: The crane may not be suited for your work, leading to delays.

- High Costs: An overbuilt crane could cost more than necessary, while an underbuilt one may not handle the load.

- Safety Concerns: A crane that doesn't match the environment or job could pose safety risks.

Brief Introduction to 10 ton Overhead Cranes (Jib Crane , Bridge Crane, Gantry Crane)

For material handling tasks involving loads up to 10 tons, three popular crane types come into play:

- Jib Crane: A compact, flexible crane ideal for tight spaces. It's perfect for small-scale lifting tasks and short distances.

- Bridge Crane: Typically used in larger spaces with high ceilings, this crane is capable of lifting heavy loads and moving them over long distances.

- Gantry Crane: A freestanding, mobile crane that can be used in outdoor environments or where overhead space is limited.

Each of these cranes is built to handle a 10 ton capacity, but their designs and applications differ. This section will compare these cranes in more detail to help you understand which is best suited for your needs.

10 ton Jib Crane

A Jib Crane is a simple, flexible lifting solution designed for small to medium lifting tasks. It consists of a vertical pillar with a horizontal arm (or jib) that extends from it. The hoist or lifting mechanism is mounted at the end of the jib arm.

- Structure: It's a fixed crane, with the base mounted to the floor or a column.

- Design: The jib arm can rotate, allowing the crane to move loads around a work area. It typically offers a limited range but excels in precision and mobility within a confined space.

Applications

A 10 ton jib crane is best for tasks that don't require high lifting heights or large spans. Some typical environments include:

- Small Workshops: Where space is tight, and lifting tasks are focused on specific points in the workshop.

- Factories: Handling materials and parts along a production line or workstation.

- Assembly Areas: Perfect for moving heavy components short distances.

Ideal Usage Scenarios

- Limited Space: If the workspace is cramped, a jib crane can be installed in the corner or along the wall.

- Low-Ceiling Environments: Ideal where overhead space is restricted, as jib cranes don't require high ceilings.

- Precise, Short-Distance Lifting: Great for areas with specific lifting points where large cranes would be inefficient.

Advantages

A 10 ton jib crane offers several key benefits:

- Flexibility and Maneuverability: The jib can rotate 360 degrees, making it easy to move materials around the workspace with ease.

- Easy Installation and Low Cost: Compared to bridge or gantry cranes, jib cranes are more affordable and easier to install. They don't need complex foundations or heavy infrastructure.

- Compact Design for Confined Spaces: The crane's small footprint allows it to fit into tight spaces, making it perfect for small workshops and factories.

Limitations

While a 10 ton jib crane is a great choice for many tasks, there are some limitations to keep in mind:

- Limited Range and Height: The jib arm is usually shorter and doesn't offer the vertical lift capabilities of larger cranes. It's best for lifting over short distances.

- Not Ideal for Large Spans or High-Duty Cycles: Jib cranes are designed for low-frequency, light to medium-duty applications. They are not suitable for heavy-duty tasks requiring large spans or continuous operation.

In summary, a 10 ton jib crane is perfect for small spaces with specific lifting needs, but it may not be the best option for large or high-frequency lifting tasks.

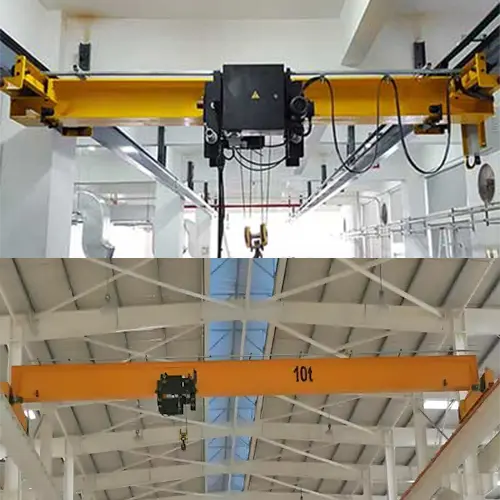

10 ton Bridge Crane

A Bridge Crane is an overhead lifting system designed for handling heavy loads in large spaces. It consists of two main components: the bridge, which moves along a set of rails or runways, and the hoist, which moves along the bridge to lift materials. Bridge cranes are often mounted on the ceiling or overhead structure, freeing up space below.

Single Girder vs. Double Girder Design:

- Single Girder: A lighter, simpler design with one main beam, suitable for lighter loads or shorter spans.

- Double Girder: A more robust design with two beams, offering higher lifting capacity, longer spans, and greater stability for heavy-duty applications.

Applications

A 10 ton bridge crane is ideal for larger environments where more mobility and lifting power are needed. Common uses include:

- Large Workshops: For moving heavy materials or machinery within the workspace.

- Factories: Especially useful on assembly lines or in areas requiring precise, heavy material handling.

- Warehouses: Efficient in large storage areas for lifting goods over long distances.

Ideal for Tasks Requiring Vertical and Horizontal Movement

Bridge cranes are perfect when the job demands both vertical lifting and horizontal movement across large areas. They can precisely position heavy loads from one side of the workspace to another, making them versatile for various tasks.

Advantages

A 10 ton bridge crane provides significant benefits, including:

- High Lifting Capacity and Efficiency: With a robust design, bridge cranes can handle heavy loads (up to 10 tons) efficiently, improving workflow.

- Versatile Range and Height: These cranes can cover large distances and lift heavy loads to greater heights, making them ideal for high-ceiling environments.

- Can Cover Large Areas with Precise Control: With the ability to move both vertically and horizontally, bridge cranes allow for accurate and flexible material positioning across wide spaces.

Limitations

While a 10 ton bridge crane offers many advantages, it does come with some limitations:

- Higher Cost and Installation Complexity: Bridge cranes are more expensive than jib cranes, both in terms of purchase price and installation. They require precise engineering and installation of overhead rail systems.

- Requires Significant Overhead Space: These cranes need high ceilings to be installed properly, making them unsuitable for low-clearance environments.

In conclusion, a 10 ton bridge crane is an excellent choice for larger workspaces that require high lifting capacities, precise control, and the ability to cover extensive areas. However, the higher cost and need for significant overhead space may be a factor to consider.

10 ton Gantry Crane

A Gantry Crane is a type of crane that operates on a freestanding structure, typically with two legs supporting a bridge. The bridge, which holds the hoist, moves along the legs, allowing the crane to cover a large area. Unlike a bridge crane, which is mounted overhead, a gantry crane's entire structure is supported by the ground, making it versatile and movable.

- Freestanding Structure: The crane consists of two vertical legs and a horizontal bridge, offering mobility across an area.

- Design: It is often equipped with wheels or tracks, allowing it to move along open spaces, such as yards, docks, or outdoor sites.

Applications

A 10 ton gantry crane is widely used in environments where mobility and flexibility are key. Some common applications include:

- Outdoor Environments: Especially useful in large open spaces such as construction sites, shipyards, and outdoor warehouses.

- Loading and Unloading Heavy Materials: Gantry cranes excel in tasks like moving heavy equipment, containers, and materials that need to be loaded or unloaded from trucks, ships, or storage areas.

Ideal for Tasks Requiring Mobility and Flexibility

Gantry cranes are ideal when there's a need to move heavy loads across wide, open spaces, often outdoors or in large storage yards.

Advantages

A 10 ton gantry crane offers several advantages for specific tasks:

- Mobility and Versatility for Outdoor Tasks: Gantry cranes can be moved easily across large open areas, making them ideal for outdoor work like construction, logistics, and material handling in yards.

- Suitable for Outdoor Environments and Large Open Spaces: They are built for harsh conditions and can handle extreme environments, making them perfect for large-scale, outdoor operations.

- Can Handle Heavy Loads Across Wide Areas: These cranes are designed to lift and move heavy materials across expansive areas, offering flexibility that other cranes may not be able to match.

Limitations

While a 10 ton gantry crane is versatile, it does have some drawbacks:

- Higher Installation and Maintenance Costs: The crane's freestanding structure requires more space and infrastructure to install, leading to higher initial costs. Additionally, maintenance can be more expensive due to its mobility and the nature of its design.

- May Not Be as Efficient in Confined Indoor Spaces: Due to its large footprint and mobility requirements, a gantry crane may not be the best choice for tight indoor spaces where overhead cranes can perform more efficiently.

In conclusion, a 10 ton gantry crane is an excellent option for outdoor and large-scale operations, offering mobility and the ability to handle heavy loads. However, it may not be the best fit for small, confined spaces due to its size and cost.

Comparison of the Three Cranes When Handling 10 ton Loads

Capacity

All three crane types—Jib, Bridge, and Gantry—can handle 10 ton loads. The lifting capacity is the same across the board, meaning each crane can lift up to 10 tons. The key difference lies in how these cranes handle the load and the environment in which they operate.

Mobility and Flexibility

- Jib Crane: The most flexible of the three, ideal for tight spaces. Its ability to rotate and move loads over short distances makes it perfect for small workshops or areas with limited space.

- Bridge Crane: Fixed in place, but highly efficient for large spaces. It can cover a wide area vertically and horizontally, making it great for large factories or warehouses where precise control and heavy lifting are needed.

- Gantry Crane: Offers high mobility, ideal for outdoor use or large open areas. It's perfect for construction sites, shipyards, or yards that need a crane to move across vast, open spaces.

Cost Considerations

- Jib Crane: The lowest cost option. With simpler installation and fewer requirements for space and infrastructure, jib cranes are the most cost-effective choice, particularly for smaller operations.

- Bridge Crane: Has a moderate cost. While more expensive than a jib crane, it offers better lifting capacity and efficiency for larger tasks. The installation can be more complex, especially with the need for overhead space and rail systems.

- Gantry Crane: The highest cost, especially for larger spans. The cost comes from its freestanding structure, mobility features, and ability to handle heavy loads across wide areas. Installation and maintenance can also be pricier.

Space and Installation Requirements

- Jib Crane: Requires minimal overhead space and has a compact design. It's perfect for spaces with low ceilings or limited floor space. Installation is simple, as it can be mounted to the floor or a column in a corner or along a wall.

- Bridge Crane: Requires a substantial ceiling height. It needs a high overhead clearance to operate effectively, making it suitable for environments with tall ceilings or industrial buildings. The installation process is more complex due to rail systems and structural needs.

- Gantry Crane: A freestanding structure that doesn't require overhead space. It's adaptable to open spaces, but it needs enough room to move and operate effectively. Gantry cranes are better suited for outdoor or large open areas where there's plenty of room to move.

In conclusion, each crane type is suited to different environments and needs. The Jib Crane is best for small spaces with limited budgets, while the Bridge Crane works well for large, high-ceiling environments. The Gantry Crane shines in outdoor or expansive spaces, offering mobility and versatility but at a higher cost.

| Criteria | Jib Crane | Bridge Crane | Gantry Crane |

|---|---|---|---|

| Capacity | 10 tons (same for all crane types) | 10 tons (same for all crane types) | 10 tons (same for all crane types) |

| Mobility and Flexibility | Most flexible, best for tight spaces | Fixed, but efficient for large spaces | Highly mobile, great for outdoor use |

| Cost | Lowest cost, easy to install | Moderate cost, more complex installation | Higher cost, especially for large spans |

| Space and Installation | Compact, needs minimal overhead space | Needs a high ceiling and large space | Freestanding, works in open spaces |

| Recommended Applications | Small workshops, assembly lines, repair areas | Large factories, warehouses, assembly lines | Outdoor sites, construction, shipyards, loading docks |

| Best Applications | Short-distance, precise lifting in small spaces | Large-scale material handling in big spaces | Moving heavy loads over wide outdoor areas or long distances |

Selecting the Right 10 Ton Material Handling Cranes

Factors to Consider

When choosing the right crane for your needs, several key factors should be considered:

Available Space and Ceiling Height:

- For small spaces, a jib crane is ideal as it requires minimal overhead space.

- Bridge cranes need high ceilings for optimal performance.

- Gantry cranes don't require overhead space but need enough room for mobility.

Frequency and Type of Load Handling:

- If the load handling is frequent and heavy, a bridge crane would be the best option.

- For occasional, light to medium loads, a jib crane may be sufficient.

- For occasional heavy load handling outdoors, a gantry crane is more suited.

Indoor vs. Outdoor Use:

- Jib cranes and bridge cranes are generally used indoors.

- Gantry cranes are best for outdoor environments, such as construction sites, shipyards, or large yards.

Budget and Installation Constraints:

- Jib cranes offer the most affordable and easiest installation.

- Bridge cranes come with a moderate cost and more complex installation.

- Gantry cranes typically have higher installation and maintenance costs.

Recommended Crane for Specific Scenarios

- Jib Crane:Best for tight, small spaces with limited overhead clearance. Ideal for light-duty applications and precision lifting in confined areas.

- Bridge Crane:Best for high-duty tasks in large indoor areas with high ceilings. Suitable for moving heavy loads over long distances and precise positioning in factories or warehouses.

- Gantry Crane:Best for outdoor or mobile applications, where flexibility and the ability to move across large open spaces are needed. Ideal for construction sites or shipyards with heavy-duty outdoor lifting requirements.

In conclusion, selecting the right crane depends on your workspace, load requirements, and budget. Consider these factors to make the most efficient choice.

| Factor | Jib Crane – Best for Small Spaces | Bridge Crane – Best for Large Indoor Areas | Gantry Crane – Best for Outdoor Use |

|---|---|---|---|

| Space Needed | Fits in tight spaces, needs little overhead room | Needs high ceilings and large indoor space | No ceiling needed, but requires open ground space |

| Load Handling | Good for occasional, light to medium loads | Best for frequent, heavy-duty lifting | Handles occasional heavy loads outdoors |

| Indoor/Outdoor | Indoor use (small workshops, repair areas) | Indoor use (factories, warehouses) | Outdoor use (construction sites, shipyards) |

| Cost & Installation | Lowest cost, easy to install | Moderate cost, complex installation | Higher cost, more maintenance needed |

| Best For | Small spaces needing precision lifting | Large spaces needing long-distance lifting | Outdoor areas needing mobility and flexibility |

Conclusion

Summary of Key Differences

Each of the 10 ton crane types has its own set of benefits and limitations, making them suitable for different tasks and environments:

Jib Crane:

- Benefits: Compact, affordable, and highly flexible for tight spaces. Ideal for short-distance, light to medium-duty lifting.

- Limitations: Limited range and height, not suitable for large spans or high-duty cycles.

Bridge Crane:

- Benefits: High lifting capacity, versatile in large indoor spaces, and capable of covering long distances with precise control.

- Limitations: Requires substantial overhead space and complex installation. Higher cost.

Gantry Crane:

- Benefits: High mobility, ideal for outdoor environments and large open areas. Can handle heavy loads across wide spaces.

- Limitations: Higher cost, especially for large spans. May not be efficient in confined indoor spaces.

Final Recommendation

To decide which crane best fits your material handling needs, consider the following:

- If you have limited space and need flexibility, a jib crane is the best option.

- For high-duty, large indoor applications, where you need to move heavy loads over long distances, a bridge crane is ideal.

- If you need mobility and are working in outdoor or expansive spaces, a gantry crane would be the most suitable choice.

By evaluating your available space, load handling requirements, and budget, you can make the most informed decision for your material handling needs.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch